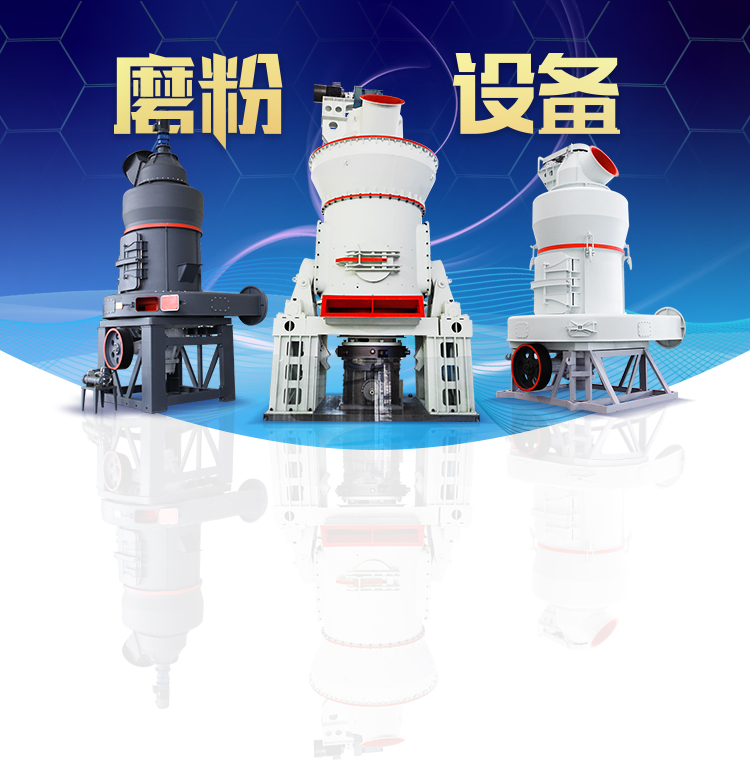

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Complete Gold Processing Plant With Cynide

.jpg)

Optimization Gold Cyanidation Process to Increase Gold

2023年2月14日 There are many several variables in cyanidation process that can be optimized to increase gold extraction Variables like free cyanide concentration, dissolved oxygen level, 2015年12月8日 Conventionally, gold ores are treated with dilute alkaline cyanide solution in the presence of oxygen to solubilize the gold The dissolved gold is then precipitated by zinc dust treatment This is the wellknown Optimizing and evaluating the operational 2022年10月15日 At present, stockpiling is the most common treatment method for cyanide tailings in gold plants, which not only causes environmental problems but also wastes valuable Review A systematic review of gold extraction: Fundamentals 2013年9月1日 Because of their ability to extract cyanide and metal cyanide complexes directly from gold plant tailings, anion exchange resins have been used in the resininpulp (RIP) Cyanide and removal options from effluents in gold mining

BACKGROUND NOTE ON CYANIDE IN GOLD MINING

2013年9月24日 Cyanide use in mining Gold typically occurs at very low concentrations in ores – less than 10 g/ton The most used process for gold extraction is hydrometallurgical recovery We offer the SART process to remove the metallurgical interference of cyanidesoluble metals and to efficiently recover and recycle cyanide in gold processingSART Process for Gold Recovery and Cyanide Management : 2011年5月1日 This paper examines the factors that influence CIP and CIL plant design and performance, and demonstrates a very simple methodology that can be used to arrive at Factors influencing the rate of gold cyanide leaching and adsorption 2018年10月23日 Plant design parameters for gold extraction, leach residence time and cyanide consumption are generally determined from standard benchscale bottle roll or agitation leach Estimating process design gold extraction, leach

.jpg)

CYANIDE RECOVERY COST EFFECTIVENESS IS WHY

2022年7月19日 uGMENT process uses a strong base resin to extract and concentrate copper cyanide from gold plant tailings solutions or pulps AuGMENT is particularly well suited to 2016年7月7日 Detoxification processes are used to reduce the concentrations of toxic constituents in tailings streams and process solutions, either by dilution, removal, or conversion to a less toxic chemical form (sometimes referred to Cyanide Destruction Methods and Processes2024年4月25日 The gold leaching process is a complex series of chemical reactions that facilitate the dissolution of gold particles from ore into a liquid medium It is crucial to have a clear understanding of the process to optimize A Comprehensive Guide to the Gold Leaching The Consep Acacia is a complete process solution to maximise recovery of gold from gravity concentrates such as those generated from a Knelson Concentrator The Consep Acacia typically achieves overall recoveries in excess of 95%, Engineering Innovation Consep

Cyanide Processing Equipment and Plant Configuration

2016年3月15日 The Jig, placed between the ball mill and classifier, is one of the most valuable and affordable improvements in cyanidation in recent years and was developed by the metallurgical engineering and Mining Equipment Companies This Mineral Jig has the marked advantage of removing a large portion of the metallic values without excessive dilution, and 2016年3月10日 PROCESS FLOWSHEET DESCRIPTION: Batch Gold CyanidationLeaching Plant ORE TREATED: Small tonnages of highgrade goldsilver ores and flotation or Jig concentrates amenable to cyanide treatment, used for treating as Gold Recovery by Batch Cyanide Leaching Plant2016年6月8日 The gold cyanidation process is the most important method ever developed for extracting gold from its ores The reasons the widespread acceptance of 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Gold Gold Cyanidation Process 911Metallurgist2018年7月10日 Processing of gold ores with high sulfide minerals is problematic as they consume cyanide and reduce gold leaching Optimization of gold leaching and cyanide consumption requires a methodology to (PDF) Leaching of gold ores with high cyanicides: a

Cyanide and cyanidation wastes management in gold leaching plants

2024年8月31日 This study assesses cyanide and cyanidation wastes management practices among small, medium and largescale gold leaching plants in Siaya County, Kenya The socioeconomic benefits of gold extraction through cyanidation of mercurycontaminated tailings notwithstanding, the study establishes inadequate cyanide and cyanidation wastes The ConSep ACACIA Reactor is a device, which utilises a high intensity cyanidation process to achieve very high, usually near total, recovery of gold from gravity concentrates The process utilises a fluidised bed and a chemical oxidant to enhance the gold dissolution kinetics to the point where the bulk of the dissolution occurs in a few hours For convenience and security, most Gravity Leaching With the ConSep ACACIA Reactor Results From The cyanide is regenerated as free cyanide and recycled to the gold extraction circuit We have designed and constructed fullscale plants, provided process review and commissioning for a plant under construction, and carried out flowsheet development and testing programs for SARTSART Process for Gold Recovery and Cyanide Management : 2015年6月24日 Here is a method on how to conduct a cyanidation bottle roll test AKA Cyanide Gold Extraction Process: 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, Cyanide Gold Extraction Process 911Metallurgist

.jpg)

Flowsheet Development of A Refractory Gold Ore To

2024年5月14日 This made development of a process flowsheet with acceptable gold recoveries difficult 4 PROCESS FLOWSHEET The project operated as a heap leach for the oxide ore capping The sulphide ore dam located several kilometres away from the process plant to a separate section of the dam The combined sulphide concentrate is further ground to an 2019年9月2日 Residence time distribution (RTD) measurement was conducted in the CIL section of a gold processing plant in order to determine the flow structure in the first tank using the 131I radioactive tracer(PDF) Kinetic control study of gold leaching with 2019年6月20日 The costeffective process replaces cyanide with a safer, less hazardous chemical reagent, thiosulphate This inorganic compound helps dissolve fine gold out of ores into a solution, which can then be recovered through further processingClean Mining launches cyanidefree gold processing2024年10月11日 Here is the brief introduction of this very popular gold ore processing technology in the world We do beleive that your gold ore processing business will be more sucessful by choosing Zenith 1 The CIL process technology The ore is ground and concentrates are produced by means of conventional flotation and gravity circuitsGold ore CarbonInLeaching (CIL) processing technology

Advances in Hydrometallurgical Gold Recovery through

2024年6月13日 Hydrometallurgical gold recovery processes play a pivotal role in the gold mining industry, contributing to more than 90% of global gold production Among the array of techniques available, the Merrill–Crowe process, adsorption, ion exchange, and solvent extraction are central in extracting gold from leach solutions While the Merrill–Crowe process and gold complex Copper and cyanide recovery from barren leach solution at the gold processing plant Oscar Lopez* BioteQ Water Chile SpA, Santiago, Chile, Managing Director, +562 2 896 9700, Nebojsa Petrovic Engineering Dobersek GmbH, Mönchengladbach, Germany, Deputy Sales Director, +49 2161 90108‐0, nebojsapetrovic@ed‐mg Svetlana Krashenina Copper and cyanide recovery from barren leach solution at the gold 2015年8月6日 What is cyanide and why do we need cyanidefree gold leaching process? Cyanide (CN –) has been used since 1889 to recover gold from hard rock As sodium cyanide (NaCN), it reacts with gold, oxygen (O), and water (H 2 O) to form a gold cyanide complex (Na [Au(CN) 2] ) and sodium hydroxide (NaOH) The chemical reaction dubbed the “Elsner Cyanide Free Gold Leaching Alternative 911MetallurgistGravity leaching has become a standard method of processing high grade gravity concentrates in gold processing plants The Acacia offers this in the safest, most cost effective and most efficient way possible and thus allows the Consep Acacia to use heated leaching for even faster kinetics and more complete leaching In 2011, an CONSEP ACACIA: THE FINEST IN LEACHING TECHNOLOGY

Cyanidefree gold goes into production CSIRO

2019年6月19日 Australia is leading the charge towards greener and safer gold production with an environmentallysuperior alternative gold recovery process technology, dispensing with toxic cyanide and mercury currently used in most gold production processes worldwide offering technology products and licences as well as turnkey processing plant options 2022年10月15日 Currently, the thiosulfate gold leaching operation at the Goldstrike mine, Nevada, of Barrick Gold Corp is the only largescale gold extraction plant with an alternate lixiviant (Azizitorghabeh et al, 2021) Although research on sulfurcontaining lixiviants has been the most common in gold hydrometallurgy in the past three decades, few Review A systematic review of gold extraction: Fundamentals cyanide process, method of extracting silver and gold from their ores by dissolving them in a dilute solution of sodium cyanide or potassium cyanide The process was invented in 1887 by the Scottish chemists John S MacArthur, Robert W Forrest, and William Forrest The method includes three steps: contacting the finely ground ore with the cyanide solution, separating the Cyanide process Gold Extraction, Leaching Recovery2021年11月9日 Oct 01, 2021 Complete removal of all pollutants in the effluents of gold processing plants is a basic necessity, while the most commonly used methods are not able to simultaneously remove heavy and toxic metals and cyanidemetal complexes; therefore, the removal of these pollutants from the effluents of gold processing plants is a major problemmplete gold processing plant with cynideHXJQ Crusher

.jpg)

Gold Extraction Recovery Processes 911Metallurgist

2016年2月29日 Heap leaching can be considered as a percolation process on ore piles The process is characterized for its economic cost against the agitated leaching process when the ore deposit has a low gold content Typically the process 2013年9月26日 Responsible management of cyanide solutions and tailings on gold processing plants worldwide is an important aspect to these operations and is regulated via guidelines provided by the (PDF) HypersalineInduced Reduction in Cyanide Ecotoxicity at Gold 2023年11月1日 Despite its toxicity, cyanide is widely present in a variety of organisms, including bacteria, algae, fungi, plants, and even animals Cyanide is commonly found as a pollutant in the wastewater of various industries, including gold smelting, electroplating, auto parts manufacturing, mining, photography, pharmaceuticals, coal coking, ore leaching, plastics, etcA review of environmental functional materials for cyanide 4 天之前 The resin based process offers a proven method for achieving virtually complete removal and efficient recovery of cyanide, dissolved base metals and precious metals from gold plant process streams For most tailings treatment applications, significant overall nett revenue will be achieved The cost of cyanide recovered is usually less than 50% GreenGold RECYN

.jpg)

Treatment of copperrich gold ore by cyanide leaching,

2015年2月1日 The ongoing depletion of gold and silvercontaining ore deposits demands a shift towards the processing of more complex sources Leaching of gold or silver from these sources, which are named refractory and are typically lowgrade, can be complicated due to one or more of the following effects: (1) kinetic or thermodynamic impediments on cyanide diffusion or on the 2016年7月14日 Cyanidation as applied to ordinary gold and silver ores is a relatively simple process When cyanicides {cyanideconsuming elements) are encountered in small amounts in the treatment of such ores, the various schemes already discussed, such as use of a lead salt or wasting barren solution, can usually be resorted to and successful operation maintainedGold Metallurgy Leaching in Cyanicides 911Metallurgist2021年6月19日 Cyanides are widely used as depressants in the selective flotation of sulphide minerals and as gold solvents in the gold cyanidation process Despite widespread application of cyanide compounds in the mineral processing industry, they are highly toxic to humans and aquatic organisms In this research study, two novel and efficient graphenebased magnetic Removal of cyanide from the gold cyanidation plant tailings 2023年10月26日 cyanide process (AVR), which was practised at the Pachuca silver mine in Mexico and at the Flin Flon mine in Canada more than 60 years ago AVR is still used today and has recently been installed at several other mines around the world The process involves acidification of the gold plant tailings with sulphuric acid, to lower the pH fromINNOVATION Cyanide management in the gold industry

AN ALTERNATIVE TO CYANIDATION IN GOLD

2022年7月20日 CYANIDATION IN GOLD PROCESSING ALTERNATIVES TO CYANIDE IN GOLD PROCESSING THIOSULPHATE LEACHING Thiosulphate leaching is a process that removes gold from gold bearing ores without the use of cyanide Although not as aggressive a leaching agent as cyanide, thiosulphate offers several technological advantages including its 2020年3月5日 Gold ore processing plants that utilize carbon adsorption technologies generate a waste activated carbon, which contains very high gold values, and the recovery of this gold represents a (PDF) Simulation of leaching process of gold by 2024年6月14日 RECOVERING CYANIDE FROM GOLD PLANT TAILINGS DR CHRIS A FLEMING, PH D –– SGS ABSTRACT The ability to recover cyanide from gold plant tailings has been known almost as long as the cyanidation process has been practiced, but there has been little incentive to process tailings in this way in the past WithRecovering Cyanide From Gold Plant Tailings2008年1月3日 In Na2S2O5air oxidation process, the time for complete process was long because of the reactions between Na2S2O5 and O2 Na2SO3 oxidation method was found to be a new method for cyanide removal Detoxification of Cyanide in a Gold Processing Plant Tailings

.jpg)

Cyanide Poisoning: Symptoms, Treatment, Complications,

2018年9月17日 Abraham P, et al (2015) Sodium nitroprusside in intensive care medicine and issues of cyanide poisoning, cyanide poisoning prophylaxis, and thiocyanate poisoning2022年8月12日 nide (NaCN) of which 90% is used in the mineral processing operations (Hilson and Monhemius 2006) In the mineral processing industry, cyanide is utilized as a depressant in the selective otation of sulphide minerals and as a leach reagent in the gold cyanidation process (Wills and Finch 2016) The environmental pollutions resulting from its misRemoval of cyanide from the gold cyanidation plant 2024年6月14日 RECOVERING CYANIDE FROM GOLD PLANT TAILINGS DR CHRIS A FLEMING, PH D –– SGS ABSTRACT The ability to recover cyanide from gold plant tailings has been known almost as long as the cyanidation process has been practiced, but there has been little incentive to process tailings in this way in the past WithRecovering Cyanide From Gold Plant Tailings2016年2月29日 Gold can be concentrated and recovered by applying different gold refining process methods and the final product has variable quality In this way, it is 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Gold Gold Smelting Refining Process 911Metallurgist

电石泥邯郸水渣矿粉厂

--制香机器价格

--裂解炭黑矿石制粉设备多少钱

--重钙碎机

--粘土湿料粉碎机,双级粉碎机

--湖北省雷蒙磨厂,2005

--丹麦斯密斯立磨如何做代理

--钾长石磨粉机械工艺流程

--山东淄博重钙磨粉机雷蒙机250100石灰石

--高压矿石辊磨机的使用

--哈尔滨荣鑫雷蒙磨除尘设备厂

--重质碳酸钙粉碳酸钙方一方多少钱

--氟石膏矿用磨粉机

--200型立式磨粉磨机

--石油焦制粉雷蒙磨磨粉设备

--市政 碳酸钙垫层

--高钙粉市场

--大型立磨立式辊磨机与重钙磨粉机雷蒙机对比

--浙江省石灰粉机械设备

--磨粉设备磨细设备

--四川新乐雅陶瓷有限公司宋银祥电话

--使用行车培训视频

--建一平方楼用沙量

--方解石矿石制粉生产线设备

--粉磨机械方解石矿渣生产线

--300粉磨生产线

--化工原料磨粉机参数

--裂解炭黑透明是钙粉吗次坚石可松系数

--江西硫铁尾矿价格行情

--重石灰石碳酸钙磨粉机功率多大

--