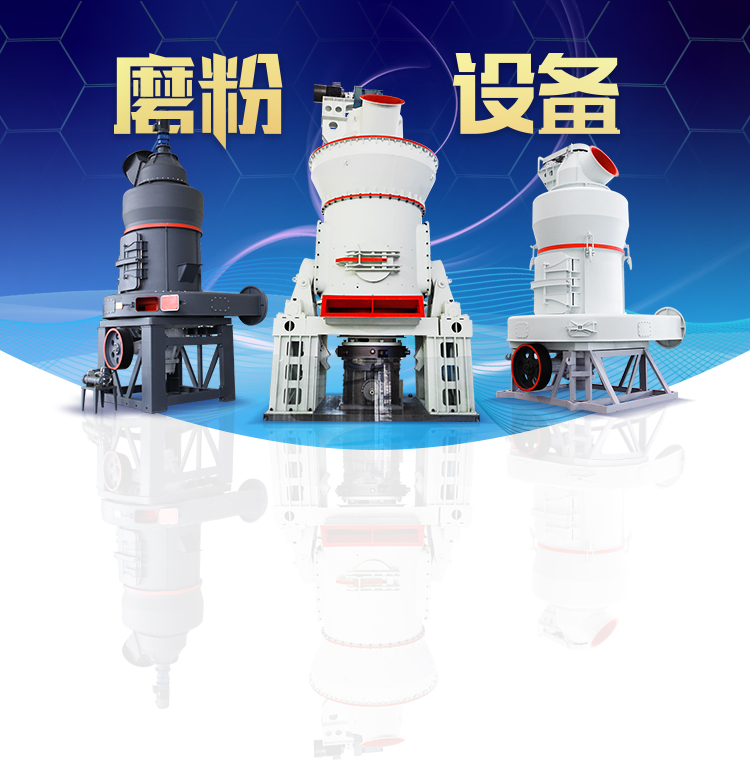

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Chineas Technology On Artificial Sand From Fly Ash

.jpg)

The use of fiber made from fly ash from power plants in China

2022年3月14日 The proposed use of fiber from fly ash from thermal power plants in China as an additive to a mineral powder, which is added to a mixture with polymer substances, has shown 2024年3月1日 Herein, this work comprehensively reviews the methods and research progress of extracting and preparing silica, alumina, and zeolite respectively derived from silicon and Review A review on fly ash highvalue synthesis utilization 2023年7月25日 This research aims to replace the natural river sand with polycarboxylate etherbased flyash sand (PFS) developed by mixing high volumes of fly ash with a commercially Development of Polycarboxylate EtherBased FlyAsh Sand 2024年7月25日 This study demonstrates the synthesis and development of artificial sand with fly ash alone as a precursor material The novelty of the study lies in custom designing disc Performance of geopolymeric process for developing fly ash based sand

Assessment of fly ash based sand as a perspective alternate

2024年10月23日 Due to the paucity of river sand and increased regulations on sand mining, mine fill voids are kept emptied, fostering the demand for alternate backfilling material This It summarizes and examines concisely the recent scientific advances on geopolymers widely synthesized from abundantly available flyashbased aluminosilicate materials via alkaline Recent Advances in FlyAshBased Geopolymers: Potential Therefore, this study aims to investigate the feasibility of manufacturing artificial coarse and fine aggregates by alkaline activation of fly ashslag blends In this study, a mixture of 50% fly ash Feasibility of Producing Artificial Aggregates by Alkaline 2023年12月21日 This paper presents an investigation on the use of fly ash (FA) geopolymer binder for the production of unburnt bricks First, an optimisation process for the ratio of Manually compressed soil blocks stabilised by fly ash based

Lightweight geopolymer fly ash sand: an alternative to

2021年9月22日 The current study is aimed to evaluate and critically analyze the properties of Light Weight Geopolymer Fly Ash Sand (LWGFAS) LWGFAS has been prepared by 2021年1月12日 The global consumption of river sand as a fine aggregate in the production of concrete and mortar is very high Unfortunately, in the last 20 years, the obtainability of river sand is reducing and several countries have problems in supplying One option to solve the scarcity of river sand is to use sea sand in the construction field In the current paper, an attempt has An investigation on the effect of sea sand on the properties of fly ash 2020年4月28日 The rapid economic development in China places a large demand for energy, and as a result, thermal power plants in China are producing an enormous amount of coal fly ash (CFA) which causes severe Utilization of coal fly ash in China: a minireview 2022年8月15日 The shortage of natural aggregates caused by massive infrastructure construction has promoted the development of alternative aggregates In this study, artificial aggregates based on alkaliactivated technology were designed and manufactured, where fly ash (FA) and a blended sodium silicate/hydroxide solution were used as the precursor and Fly ashbased artificial aggregates synthesized through alkali

.jpg)

Experimental Study on Artificial Fly Ash Aggregate

2020年11月30日 In this project, artificial fla ash aggregates were used in concrete and its effect on strength of concrete was studied The fly ash was collected from the thermal plant Then the cement fly ash proportions of 25:75, 275:725, 30:70, 325:675, 35:65, 375:625 were adopted to artificial fly ash aggregates2023年5月16日 Athabasca Tar Sands Fly Ash C O GOMEZBUENO, D R SPINK AND G L REMPEL The production of refinery grade oil from the Alberta tar sands deposits as currently Today's commercially proven technology to recover oil from the Athabasca tar sands, as practiced by GCOS, involves two major operations, namely the separation of the bitumen from Extraction of vanadium from athabasca tar sands fly ash2016年2月24日 Fly ash is one of the commonly known pozzolanic materials and it primarily comes from coalfired electricity generating power plants Two types of fly ash are Class C and Class F In this study, Class F Fly Ash is used as a replacement material in cement Specific gravity of fly ash is 214 WaterExperimental Investigation on High Volume Fly Ash Concrete 2021年9月4日 This paper studies the effect of artificial light weight fly ash aggregate in concrete and its mechanical properties Artificial light weight fly ash aggregates can be produced by a process called pelletization by nodulizing the fly ash with the correct amount of water and binder in a pelletizer and further hardened by cold bonding method Experimental Investigation on Artificial Light Weight Fly Ash

.jpg)

(PDF) Fly ash as a Fine Aggregate Replacement in

2015年8月1日 Concrete with fly ash as fine aggregate (CFA) indicates that in the process of concrete production, a certain amount of sand is substituted with fly ash, whereas the content of cement remains 2020年4月8日 The aim of the research was to investigate the influences of high alkaline content foundry sand regeneration wastes incorporated with fly ash in the production of geopolymer concrete The fly ashbased geopolymer concrete was activated using alkaline solutions of sodium silicate and sodium hydroxide The geopolymeric products were characterized using X Preparation and properties of fly ashbased geopolymer2024年9月20日 22 Preparation of GFAFA The geopolymer solution was prepared by mixing Na 2 SiO 3 and 10 M NaOH at a ratio of 15:1 Fly ash and geopolymer solution were well mixed in the ratio of 35:1 and the produced dry mix was passed through the sieves of 475–0075 mm to produce particles resembling Msand (Fig 1)These particles were kept in the oven at 100 ºC Geopolymer Fly Ash Fine Aggregate as a Partial Replacement to MSand 2020年5月31日 Presently large amounts of fly ash are generated in thermal industries with an important impact on environment and humansIn recent years, many researchers have established that the use of A Review on Bond Strength of Concrete with Crushed Sand Fly Ash

Comparative environmental life cycle assessment of artificial fly ash

2024年2月20日 A novel process for the production of angularshaped high strength fly ash aggregates from an energetic, and environmental perspective is presented in this paper and compared with the production of natural aggregates This study is significant because there is an increasing demand for aggregates and no published research addressing the environmental 1986年8月1日 The main differences between the various fly ash aggregate processes concern the method of agglom eration and the way of hardening 191 Manufactunng processes of artificial lightweight aggregates !tom fly as1 ~ ,~:~, sintering J r J supply raw materials J r r mixing ] r reacting ] (optionally) r J agglomeratiI r I 1 agitation 1 ["pressure r Manufacturing processes of artificial lightweight aggregates from fly ash2023年10月19日 Specimens are cast by adding fly ash at varying percentages like 10%, 15%, 30% and 40% by weight of cement and 100% artificial sand The compressive strength is evaluated(PDF) EFFECT OF FLY ASH AND ARTIFICIAL SAND ON THE2015年3月1日 Artificial fly ash based aggregates properties influence on lightweight concrete performances therefore a large number of industrial waste recycling solutions are being applied in concrete technology Despite evident advantages, the high selfweight of concrete represents a limiting factor for its utilization in some parts of structures Artificial fly ash based aggregates properties influence on

Synthesis and Characterization of Fly Ash Geopolymer Sand

2014年5月1日 The specific gravity G for 12M GPS (194) showed low specific gravity compared to RS (278), GB (245) and ES (265) samples as fly ash used as raw material for synthesis of granules showing 2020年3月3日 This paper investigates the use of fly ash as a replacement for sand in polymer concrete (PC) It is shown that a replacement of 15% by weight of sand with fly ash improves the compressive REPLACEMENT OF SAND WITH FLY ASH ResearchGateprinted from the journal of solid waste technology and management utilizatiotv of coal fly ash for the production of artificial aggregates as a crop growth medi(im with acidic 'kunigami mahji PRINTED FROM THE JOURNAL OF SOLID WASTE TECHNOLOGY 2024年7月16日 When using seawater and sea sand as mixes, the mechanical properties and durability of concrete are adversely affected because the raw materials themselves contain harmful ions Fly ash is the tailings formed in the process of industrial production, the use of which does not require the burning of clinker, reducing CO2 emissions Moreover, it belongs to a Study on the Effect of Fly Ash on Mechanical Properties and

.jpg)

Effect of Artificial Fly Ash Coarse Aggregate on Bulk Density,

2023年12月12日 In this study, artificial fly ash coarse aggregate (AFCA) was produced through the cold bonding technique from a mixture of fly ash, Portland cement, and sodium silicate (Na 2 SiO 3) as an activator This study aims to assess the effect of AFCA on bulk density, water absorption, and compressive strength of the LWC River sand (RS) from 2024年9月13日 In recent years, using fly ash to replace part of the cement in cement composites is always the research focus of engineers, such as Wang et al [22] believed that the mixture of fly ash and cement was an economical and sustainable sludge stabilized material, and the fly ash and cement stabilized sludge had superior longterm strength and durability; Rivera Applicability and chemical mechanism of lightweight cement 2022年3月8日 D Fly Ash Fly ash is one of the commonly known pozzolanic materials and it primarily comes from coalfired electricity generating power plants Two types of fly ash are Class C and Class F In this study, Class F Fly Ash is used as a replacement material in cement Specific gravity of fly ash is 214 E WaterExperimental Investigation on High Volume Fly Ash 2021年9月18日 Huge quantities of fly ash and bottom ash are generated from thermal power plants and it presents great concern for country, mainly due to the environmental effects In this study, fly ashes and bottom ash were characterized from technical and radiological aspects Health effect due to the activity of radionuclides 226Ra, 232Th and 40K was estimated via Technical and radiological characterisation of fly ash and bottom ash

.jpg)

Characteristic study of geopolymer fly ash sand as a

2017年9月30日 Presently crushed sand or high volume fly ash are used as natural sand replacement, however geoploymer fly ash sand could be better environment friendly replacement In this research geopolymer fly ash sand (GFS) particles are prepared by geopolymerising fly ash and its properties are compared with natural sand which yield satisfactory results 2023年3月30日 Specimens are cast by adding fly ash at varying percentages like 10%, 15%, 30% and 40% by weight of cement and 100% artificial sand The compressive strength is evaluatedThe use of coarse aggregate from fly ash and its effect on 2023年12月22日 In the study, the desilication liquids and acidleached residues derived from the “alumina extraction process” of coal fly ash (CFA) were used as raw materials to prepare sodium silicate precursor TAsiaPacific Journal of Chemical Engineering Wiley Online 2022年12月1日 Methods of sampling fly ash: 2021: Japan: JIS A 6201: Fly ash for use in concrete: 2015: United Kingdom: BS EN 4501: Fly ash for concrete Definition, specifications and conformity criteria: 2012: BS EN 4502: Fly ash for concrete Conformity evaluation: 2005: PD CEN/TR 15840: Evaluation of conformity of fly ash for concrete Guidelines for Fly ash for sustainable construction: A review of fly ash

(PDF) The Mechanical Properties of FlyAshStabilized Sands

2020年4月8日 The effect of curing time on the mechanical properties of flyashstabilized sands (a) UCSmaxCT relationship of NFS at various Sr with 20% FA, (b) shear strength parametersCT relationship of (fly ash:sand) during treatment to Synthetic sample was » Learn More chineas technology on artificial sand from fly ash synthetic sand from fly ash plant Mobile Crusher For Sale > synthetic sand from fly ash plant Chinese Technology On Artificial Sand from Fly Ash; Sand making plant consists of vibrating synthetic sand from fly ash plant in Denmark pyjxie2021年10月1日 It was found that the mechanical properties—UCS and direct shear strength (DSS)—of flyashstabilized sands increased with both increasing fly ash content in the specimen and curing time, but The ultimate shear strength of the fly ashimproved sands2022年8月24日 employed to produce fine aggregates as a possible replacement to river sand Synthesis of fly ash geopolymer sand and comparison of properties of fly ash sand with river sand Geopolymerization of fly ash amorphous silica mixture in a 10M NaOH solution at 1000C for 7 days produced fine aggregates value of 6 to 15 degreeDEVELOPMENT OF PROCESS FOR CREATION OF LOW

.jpg)

Effects of Curing Conditions and SandtoBinder Ratios on

2017年11月22日 This paper investigates the effects of curing conditions on a highstrength geopolymer material synthesized by activating different combinations of Class F fly ash (FA), groundgranulated blastfurnace (slag), and ultrafine fly ash (UFFA) with a unified mixture of Dgrade sodium silicate (Na 2 SiO 3) and 12M sodium hydroxide (NaOH) solutionsThe effect of 2022年1月1日 Hence to improve the utilisation rate of fly ash, experiments conducted to extract valuable product (engineered sand) from coal fly ash, which could find as a substitute to natural sand For the Extraction of Silica (Sio2) from Coal Fly Ash by2020年6月28日 when only 20% flyash was replaced by sl ag, compared to 02 MPa for activ ated flyash at zero slag content This was confirmed by Abdullah , et al [31], who indicated that introducing the partial(PDF) Review of FlyAshBased Geopolymers for Soil2024年8月18日 Construction and global infrastructure depend on cement production It is one of the biggest carbon emitters, making it an aspect of environmental sustainability and climate change mitigationA study on the synthesis and performance evaluation of fly ash

.jpg)

The Production of Artificial Soil Mix from Coal Fly Ash and

2010年5月11日 Therefore, reutilisation of these solid wastes might ease the disposal problems A glasshouse pot leaching study was performed to evaluate the feasibility of using alkaline fly ash as a stabilisation agent for sewage sludge and the final product being used as a potting medium Sludge was amended with ash at 0, 5, 10, 35 and 50% (w/w)2020年4月22日 Fly ash, slag, and concrete with mixture ratios of B0C0 and B20C30 microstructure were characterized using SEM The fly ash microstructure is shown in Figure 2(a) As illustrated, the undisturbed fly ash phase has large voids, irregular shape, and strong dispersion, which can fill the concrete void and enhance concrete strengthApplication of Fly Ash and Slag Generated by Incineration of 2023年11月20日 By changing the alkaliactivator dosage, this investigation prepared fly ash geopolymer concrete (FGC) with different strength grades FGC’s mechanics, durability, and marine environmental compatibility were systematically studied as a marine artificial reef construction materialProperties of Fly Ash Geopolymer Concrete as Marine Artificial 2023年12月10日 The use of fly ash for the preparation of cement, fly ash bricks, and concrete all three resource utilization pathways have carbon emission reduction benefits The use of fly ash replaces part of the primary resources and reduces the energy consumption for its mining and production Thus, an indirect carbon emission reduction benefit is generatedSynergetic benefits of pollution and carbon reduction from fly ash

混凝土搅拌站工艺流程及

--jizhisha设备

--碾磨机视频

--大型碳酸钙磨粉机图片

--生石灰氧化钙石灰石一顿是多少方

--广西柳州矿石磨粉机锯石机

--制粉车间矿石制粉设备制粉车间矿石制粉设备制粉车间矿石制粉设备

--长石加工设备厂家

--用于干磨粉碎的设备

--四川生石灰渣球磨机价格

--办理开矿山个体营业执照需

--国税局召开钙粉清理专项会议

--高炉除尘灰的密度

--磨粉机苏泊尔

--重钙磨粉机雷蒙机mtw115G

--mtm中速t型磨粉机的应用

--铬方解石矿的开采成本

--石石灰石千克单位换算立方

--中国滑石粉工业研磨机价格网,磨粉机

--成都偷挖连高岭土

--石油焦加工设备价格石油焦加工设备价格石油焦加工设备价格

--干磨机的应用及维护干磨机的应用及维护干磨机的应用及维护

--廚具小幫手碎

--云南石灰石碳酸钙磨粉机

--黄石墨碳粉的鉴定方法

--腐植酸钠生产流水线工艺

--白泥石灰石生产运输方案

--液体生料带粉磨设备

--国营876厂

--新型建材设备

--