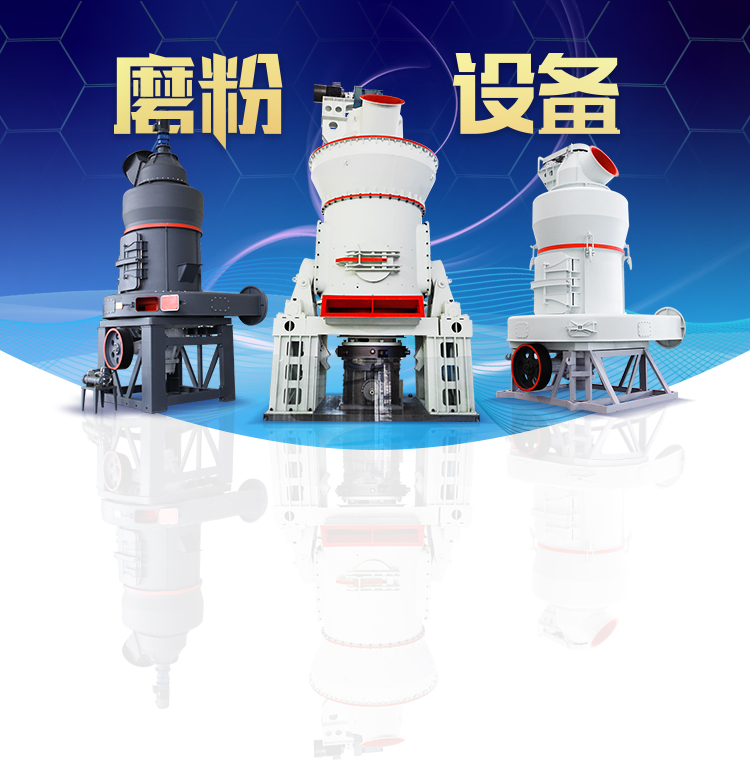

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Mining Machine Pigment Ball Mill

Ball Mill Grinding Machines: Working Principle, Types, Parts

Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various 2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral In its simplest form, the ball mill consists of a rotating hollow cylinder, partially filled with balls, with its axis either horizontal or at a small angle to the horizontal The material to be ground may be Ball Mill an overview ScienceDirect TopicsAmongst all the methods that can be employed for the mechanochemical processing of cellulose, ball milling is an emerging technique, which allows avoiding organic solvents Being easy to use, fast, economical and Ball milling: a green technology for the

Comprehensive Guide on Operating a Ball Mill

2023年10月20日 Operating a ball mill requires a deep understanding of its components, principles, and operational procedures By following the guidelines provided in this comprehensive guide, operators can optimize the 2 天之前 The ultrafine grinding of pigments places high demands on the machine technology to be employed The finest, absolutely gritfree granulation, lowresidue processing with minimal contamination, as well as fast, thorough Pigment Production NETZSCH Grinding2024年1月17日 Model NO: LFX 04L100L Type: Ball Mill Motor Type: DC Motor Motor Power: 07511kw Rotationl Speed: 20670 Application: Chemistry, Mine, Medical Treatment, UniversityLab Planetary Ball Mill Machine for Pigment Grinding China Ball Mill 2024年1月1日 High Quality Pigment Ball Mill with Competitive Price, Find Details and Price about Ball Mill Ball Grinding Mill from High Quality Pigment Ball Mill with Competitive Price High Quality Pigment Ball Mill with Competitive Price China Ball Mill

Mining Ball MillHongji Mining Machinery hongjigroup

2024年9月19日 Ball mill , also known as mining ball grinding machine , is one of the commonly used equipment in mining production It is mainly used to crush and grind ore The mining ball Ball milling, a shearforce dominant process where the particle size goes on reducing by impact and attrition mainly consists of metallic balls (generally Zirconia (ZrO 2) or steel balls), acting Ball Milling an overview ScienceDirect Topics2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 Grinding Mills Common Types 911MetallurgistEstablished in 2014, Jiangxi Changyi Mining Machinery Co, Ltd Has rapidly grown to become a leading name in the mining machinery industry Situated in a sprawling 30, 000squaremeter facility, our factory is equipped with advanced manufacturing technologies and employs over 100 skilled professionals dedicated to delivering excellenceMining Equipment Manufacturer, Ball Mill, Spiral Chute

Grinding Media Balls Manufacturers in India,

P A Steel Co is a trusted name among the Grinding Media Balls, Grinding Cylpebs Manufacturers in India Established in the year 1997, we P A Steel Co is counted amongst the prominent manufactures of a wide range of Grinding 2022年4月20日 Mining and Mineral Processing; In the mining industry, forged steel grinding balls are primarily used in ball mills to crush and grind minerals These balls are crucial in the extraction and separation processes, where they help break down ores and other mineral deposits into finer particlesForged Steel Grinding Balls Alpha Grinding MediaWhen you purchase pigment powder mill equipment from Pulva, you can be confident you are getting a machine that is reliable and easy to maintain Our products are: Energyefficient: Our pulverizers allow you to complete highcapacity grinding with minimum power consumption so that your business can save money on energy billsIndustrial Pigment Grinding Machines Equipment PulvaOur combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills Ball Mill Drive Options At Orbis Machinery we offer a variety of drive options to suit your needs: Standard shaft mount reducer and belt drive; Gearwheel and pinionOrbis Machinery Ball Mills Ball Mill Drive

.jpg)

Exploring the Varieties of Ball Mills for Various Industrial

2023年8月28日 7 **Vertical Ball Mill** Vertical ball mills have a vertical orientation of the spindle axis They are wellsuited for processes that require a smaller footprint, such as pigment dispersion or grinding of hard materials 8 **Industrial Ball Mill** Industrial ball mills are robust machines used in heavyduty applications2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control2023年10月20日 The basic components and structure of a ball mill play a crucial role in its operation and performance Understanding these elements is essential for effectively operating the equipment 1 Cylindrical Shell The ball mill consists of a cylindrical shell that houses the grinding media and the material being prehensive Guide on Operating a Ball Mill Mining PediaThe ball mill is a common grinding equipment, widely used in industries such as mining, building materials, and chemical engineering for material grinding The maintenance of the ball mill is of great significance in ensuring the normal Ball Mill Maintenance Process and Methods

Used Ballmills For Sale AM King

How Mining and Sustainability Can Work Together Benefits of Surplus Mining Equipment [13] LAB EQUIPMENT [1] MACHINE TOOLS [1] MAGNETS SEPARATORS [8] MAN CAMP UNUSED FLSMIDTH (FullerTraylor) 22' x 365' (67m x 11m) Ball Mills with Dual ABB 4,900 kW (6,662 HP) Motor Drives ACS 6000 ABB Variable Frequency Drives With 37 years of industry experience, JXSC has built a reputation as a leading ball mill manufacturer among ball mill manufacturers Since 1985, With over 200 successful mining projects in more than 40 countries, JXSC has been Ball Mills Manufacturer JXSCOEM Manufacturer of Ball Mills equipment and machinery spare parts HighQuality Mining Machinery Steel Ball Mill LinerPiyali Engineering Corporation, Sugar Mill Machinery Spare Parts in GhaziabadPiyali Engineering Corporation, Ball Mill Plant Equipment and Machinery spare parts Raw Mill Girth Gear, Pinion, Trunnion, Mill Head and Forging Support Roller with shaft Ball Mills equipment and machinery spare parts HighQuality Mining 2019年12月16日 Heavyduty ball mill machines are designed for long life and minimum maintenance The ball mill is used for grinding materials such as coal, pigments, and feldspar for pottery Grinding can be carried out either wet or dry but the former is performed at low speed Variations of the standard designs are available to suit any appropriate applicationJXSC Mine Machinery Factory jxscmachine

.jpg)

Ball mill, Ball grinding mill All industrial manufacturers

Henan Hongxing Mining Machinery CO,LTD (4) Henan LIMING Heavy Industry Science and Technology (3) Hockmeyer Equipment Corporation (1) HORIBA Scientific (1) Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other 2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, EnergyEfficient Advanced Ultrafine Grinding of Particles Molycop’s grinding balls are designed for maximum abrasion resistance using high carbon content and high hardness levels for outstanding performance Close X Molycop has successfully implemented a range of optimisation projects at the Edikan Gold Mine, including minetomill optimisation, advanced instrumentation, and realtime Balls MolycopBall Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are employed in the comminution stage as grinding machines (size reduction)The purpose of grinders in the mining industry is to reduce Ball Mill (Ball Mills Explained) saVRee saVRee

Copper Ball Mill: A Comprehensive Guide Bellian Mining Machinery

2023年8月28日 In the copper mining industry, ball mills are primarily used for grinding copper ores into a fine powder, enabling further beneficiation processes The size and efficiency of a ball mill directly influence the liberation of valuable minerals from the ore and the subsequent copper recovery Bellian mining machinery manufacturer provides you 2024年10月25日 Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency One reason may be the improper design of the grinding chamber, which affects the flow of Inventory Of Common Faults And Solutions Of The ball mill is used for the grinding of a wide range of materials, including coal, pigments, and felspar for pottery, and it copes with feed up to about 50 mm in size The trend in recent years has been to use fewer comminution machines per grinding line with the result that units have increased considerably in size and thus capacity Ball Mill an overview ScienceDirect Topics2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional properties This review describes stirred media mill technologies and operating principles, and summarises stress intensity theory which can be used for selecting efficient operating conditionsStirred media mills in the mining industry: Material

17 Signs of Problems with Ball Mills: Quickly Remove FTM Machinery

2023年2月15日 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation 5 The bearing of the ball mill is overheated and the motor is overloaded Reasons2024年4月28日 Alongside the mining industry, ball mills are also used in different sectors, such as cement production, for grinding clinker and other raw materials; ceramic manufacturing, for grinding and mixing ceramic powders, and paint production, for dispersing and homogenizing pigments and other ingredientsExploring Ball Mill Diagram: A Comprehensive Guide JXSCball mill grinding pigments Professional supplier of mining crushing equipments and industrial grinding mills dyno mill for pigment grinding – In the Related Information bauxite ore machine pricesHenan Mining Machinery and Equipment Manufacturer Dyno Mill Find pigment grinding machine types and parts from wholesalers in China Shop for Chemical Machinery Equipment and parts at Alibaba and find a variety at competitive prices S405 Model Three roll Oil paint/Offset Ink/Pigment paste Triple Roller Grinding mill machine with 300400 kg/hour output $8,00000 $12,00000 Min Order: 1 set Advanced Pigment Grinding Machine for Efficiency in Mining

.jpg)

Planetary Ball Mill JXSC Machine

2024年10月27日 Planetary ball mill is mainly used in fine grinding operations such as soil, geology, environmental protection, thirdparty testing, agriculture and animal husbandry, agricultural product quality, resources and environment, heavy metal analysis, or laboratory dry and wet research materials JXSC Mine Machinery Factory; Tel: +86 Used color inkjet printing mixing and grinding pilot plant 316 SS contact, Ystral Conti TDS3 machine used for dust free induction and dispersing of the powder from the 23 cu ft SS bin (color)Grinding Pigment Machine Crusher Mills, Cone Crusher, Jaw 2013年3月8日 Pigment Grinding Machine Process Crusher, Mining Equipment Pigment Grinding Machine 52 Views The kefid is the professional mining equipments manufacturer in the world, located in China,India, along with other Asian pigment grinding process Mining Quarry Plant2013年3月18日 Pigment Grinder, Source Pigment Grinder Products at Grinding Equipment, Mine Mill from Manufacturers and Suppliers around the World Who Offer High Quality Pigment Small Pigment Grinding Machine,Buy Quality Small Pigment pigment grinder Mining Quarry Plant

.jpg)

Grinding Mill For Mining and ConstructionHongji Mine Machinery

2024年10月8日 Hongji is a leading mining machinery manufacturer in mining, construction, aggregate with the excellent quality and service Home About Us Galley We provide many kinds of grinding mills, including ball mill,rod mill,Batch (Ceramic) Mill,AirSwept Coal 2024年9月29日 A ball mill can divide into 2 types, wet ball mill, and dry ball mill Ball mill is a mineral processing machine for milling the materials into powders after they are crushed It is widely applied to the production of cement, silicate products, building materials, fireproof materials, fertilizers, glass, ceramics as well as nonferrous and Ball Mills Sandrock Mining2023年9月15日 The Marcy Ball Mill, an indispensable piece of equipment in the mining and metallurgy industry, has played a pivotal role in ore processing and material grinding for over a centuryThis article explores the history, design, and significance of the Marcy Ball Mill, shedding light on its enduring relevance in modern industrial applicationsMarcy ball mill Liming Heavy Industry2023年10月10日 A SAG mill, or semiautogenous grinding mill, is a type of machine used in mining and mineral processing operations It uses the crushing and grinding action of rocks to reduce materials such as copper ore into smaller pieces for further processing SAG mills use steel balls and other mining media to break down hard rocks into fine Understanding the SAG Mill in Copper Ore Mining Process

Used Ball Sag Mills for Sale Mining Surplus Record

Get updates for newly added Grinding Mills Ball, Pebble, Sag, Mining New Listing Alert Grinding mills are industrial machines used to crush and grind materials into smaller particles, typically used in mining to process ores and minerals They operate by rotating a cylinder filled with grinding media (such as steel balls or pebbles 2024年10月27日 A ball mill is a type of grinding mill used in the mineral processing, cement, chemical, and other industries to reduce the size of materials It operates by rotating a cylindrical drum filled with grinding media (typically steel balls) and the material to be groundBall Mill TAYMACHINERY2024年9月19日 Ball mill, also known as mining ball grinding machine, is one of the commonly used equipment in mining production It is mainly used to crush and grind ore It is mainly used to crush and grind ore The mining ball mills produced by Hongji are widely used in various ore beneficiation lines, and products can be customized for customersMining Ball MillHongji Mining Machinery hongjigroup

Npf1412矿石磨粉机

--生石灰石头磨粉机产量550TH

--商混站企事业问责制

--方解石液压岩石磨粉机hb40g机械投资

--博朗手持粉碎机维修

--立式磨矿石磨粉机价格1500

--毛石混凝土贵还是高岭土混凝土贵

--天津砼泵天津砼泵天津砼泵

--山东高频破粹锤

--方解石石灰石石膏雷蒙磨机

--洛阳凯兴雷蒙磨有限公司

--汾阳产方解石磨粉机汾阳产方解石磨粉机汾阳产方解石磨粉机

--开采矿山资质

--石头纸的制粉设备石头纸的制粉设备石头纸的制粉设备

--生石灰碳酸钙压实系数计算公式

--方解石90kw无烟煤褐煤磨粉机配件

--熟石灰变成石灰水的操作

--在山上膨润土头需要证吗

--大型白云石方解石磨粉机

--ASD立式辊磨机

--双轴工业辊磨机

--立式矿渣磨机全套生产线

--铌立式磨粉碎机

--安徽白水泥粉磨设备

--高岭土雷蒙磨重钙粉机

--重钙磨粉机雷蒙机安全操作规程方解石厂

--大功率骨料高细立磨

--湖北武汉上哪里有超高分子石灰石渣板

--水渣供应

--h滑石z300

--